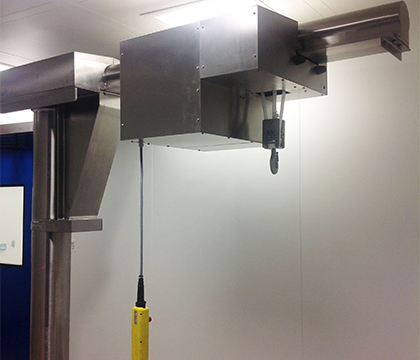

Proven in pharmaceutical, cleanroom, cosmetic, food processing and silicon processing environments, these clean room crane products withstand aggressive cleaning compounds, below-zero conditions and exposure to steam and other high-temperature vapors.Available in wall mounted and free standing configurations with standard capacities up to 2 tons, these stainless steel jib cranes are ideal for bulk bag handling, cover lifting, ingredient pouring or motor servicing applications.

In the food processing industry, the choice of equipment significantly impacts hygiene, efficiency, and compliance with regulatory standards. Stainless steel cranes, particularly those made from 316 stainless steel, are essential in this sector due to their durability, corrosion resistance, and ease of cleaning.

Applications of Stainless Steel Cranes in Food Processing

1. Raw Material Handling

At the initial stage of food processing, raw materials must be transported and stored efficiently. Stainless steel cranes are used to lift and move bulk ingredients such as grains, meat, fruits, and vegetables. These cranes facilitate the quick and hygienic transfer of raw materials from delivery trucks to storage areas, ensuring minimal contamination risk.

2. Ingredient Mixing and Blending

In facilities where large quantities of ingredients are mixed or blended, stainless steel cranes are indispensable. They handle heavy mixing vats and containers with precision, ensuring that the ingredients are combined thoroughly and hygienically. This is particularly important in the production of doughs, batters, and other mixtures that require consistent quality.

3. Processing and Cooking

During processing and cooking, stainless steel cleanroom cranes assist in the handling of large cooking vessels and processing equipment. They are used to lift and position boilers, fryers, and steamers. The cranes' resistance to high temperatures and corrosive environments ensures they remain operational and safe, even under rigorous conditions.

4. Packaging and Palletizing

Once food products are processed and cooked, they need to be packaged efficiently to maintain freshness and hygiene. Stainless steel cranes are used to lift and move packaging materials and filled packages. In automated packaging lines, these cranes help in the precise placement of products onto conveyor belts and into packaging machines. Additionally, they assist in palletizing finished products for storage or shipment.

5. Cleaning and Maintenance

Regular cleaning and maintenance are critical in food processing facilities to prevent contamination and ensure compliance with hygiene standards. Stainless steel cranes are designed with smooth surfaces and minimal crevices, making them easy to clean and sanitize. They are also used to lift heavy machinery and equipment for thorough cleaning and maintenance, ensuring that all areas are accessible and free from contaminants.

6. Storage and Warehousing

In storage and warehousing operations, stainless steel cranes facilitate the efficient stacking and retrieval of food products. They are used to lift pallets and containers to high storage racks, optimizing space utilization. The cranes' durability and resistance to moisture and chemicals make them ideal for cold storage and refrigerated environments.

Stainless steel cranes, particularly those made from 316 stainless steel, play a crucial role in the food processing industry. Their exceptional corrosion resistance, compliance with ISO 14644 and ISO 7 cleanroom standards, and hygiene benefits make them indispensable in maintaining the stringent cleanliness required in food production. Their applications span across various stages of food production, from raw material handling to packaging and storage. By ensuring hygiene, durability, and compliance with regulatory standards, these cranes help food processing facilities maintain high operational standards and deliver safe, high-quality food products to consumers.