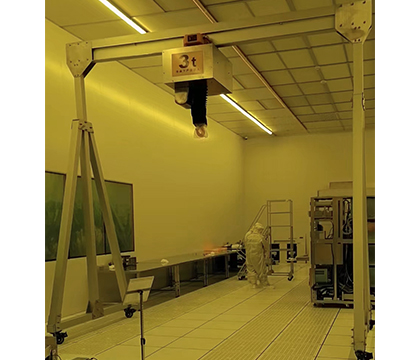

Clean Room Crane with Belt Hoist

The cleanroom crane is equipped with a high-performance belt hoist, which can achieve precise and smooth material lifting in the cleanroom, ensuring that no particles or contamination are generated during operation.

+86-15201969650

info@kfcscrane.com

No.5358 Huyi Road, Jiading District, Shanghai, China

Clean room crane with belt hoist can achieve accurate and smooth material lifting in clean rooms, ensuring that no particles or contamination are generated during operation. The high load capacity and stability of the belt hoist make it easy to handle various light and heavy materials, while its unique sealing design effectively avoids the release of pollutants, meeting the strict requirements of clean room hygiene and cleanliness.

The fiber belt is not only light in weight, which reduces the burden on the equipment, but also has better wear and tensile resistance, and can withstand higher loads without deformation. The fiber belt has a smooth surface and good elasticity, which can effectively reduce the impact and damage to the hoisted objects, and is particularly suitable for environments that require precise handling. When used with a cleanroom crane, the fiber belt as the transmission medium of the belt hoist can reduce the generation of particles, meet the high hygiene standards of the cleanroom, and ensure that the environment will not be polluted during material handling.

Advantages of cleanroom crane with belt hoist

● It can operate stably in the cleanroom, avoid any pollution to the environment, and meet strict cleanliness standards.

● The belt hoist has higher precision control and can lift and carry objects smoothly and accurately.

● It can extend the service life of the equipment, reduce maintenance costs, and ensure long-term stable operation of the equipment in harsh environments.

● Fiber belts are lighter than traditional steel chains, which reduces the load on the equipment and improves the operating efficiency of the crane.

● The sealing design of the belt hoist reduces air pollution and is suitable for clean rooms, high-standard laboratories and production environments.

The belt hoist cleanroom crane we produce is designed for controlled environments and is widely used in electronics, pharmaceuticals, food and other industries. The crane is equipped with a high-performance belt hoist and uses fiber belts instead of traditional steel chains. It is light, durable, low-noise and low-vibration, effectively reducing particulate matter and pollution generated during material handling, ensuring compliance with the strict standards of clean rooms.