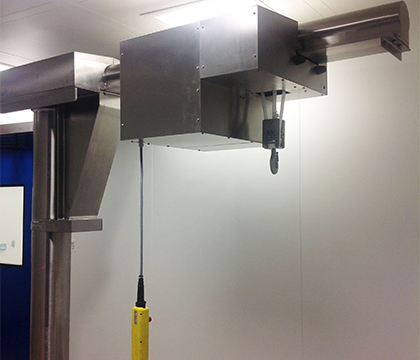

Introduction to stainless steel cantilever crane

The main parts of the stainless steel cantilever crane are all made of stainless steel, which is suitable for use in places with corrosive gas. At the same time, the stainless steel cantilever crane is also equipped with explosion-proof motor and explosion-proof travel switch, which is suitable for places with explosive gas or explosive gas mixture.

It is mainly composed of fixed column, movable column, cantilever, roller device, electric push rod and other components. It has simple structure, light and flexible rotation, and the cantilever can be suspended for 360°, with large working space.

Installation Of Stainless Steel Cantilever Crane

After the equipment is transported to the site, the product and technical documents shall be checked for lack of live losses according to the packing list, bending and torsion deformation of stainless steel cantilever beam and corrosion of shaft caused by transportation. Bruises, etc. should be corrected or restored respectively.

When installing the column, keep the column vertical to the ground, tighten the screws of the baseboard firmly without loosening, and the floor and foundation should fit well. If equipped with an electric hoist, the foundation should be embedded with cables and grounding facilities. The embedded cables are led out from the foundation, and the grounding resistance should not be greater than 4 ohms.

Please install the beam in the following order. First lift the beam horizontally, and insert the rotating shaft into the rotating cylinder from the upper and lower supporting plates. Then install the reducer on the support plate and the electric hoist on the stainless steel cantilever beam track. Connect and install all electrical appliances on the beam, and leave power lines with appropriate length.

Operating procedures for stainless steel cantilever crane

1. Before using, the operator should check whether there is any fault in the switch button and steel wire rope limit. If there is any problem, it should be repaired in time before use. After use, it should be placed in a safe area.

2. Concentrate when lifting the workpiece, put one hand on the operation switch, and grasp the smooth reciprocation of the workpiece with one hand. It is not allowed to chat while lifting to avoid danger.

3. When lifting any workpiece, be sure to try to lift it. The hook should be vertical. In case of imbalance, adjust the hook in time. Oblique lifting is not allowed. Try lifting again to keep the workpiece stable before lifting.

4. Overload lifting is not allowed, and lifting any workpiece is not allowed to exceed 500kg, otherwise it will be punished for violating the operating procedures.

5. When lifting the workpiece, it is not allowed to be too high from the ground. It should be about half a person high. If there is an object passing over, it should be careful not to collide.

6. When lifting any workpiece, pay attention to the operation status at any time, stop lifting immediately in case of abnormal noise and abnormal phenomenon, and report it in time for treatment. It is not allowed to work with disease, otherwise it will be punished according to the violation of operating procedures.

7. When using the stainless steel cantilever crane to calibrate the workpiece, the power supply of the machine tool must be turned off to avoid touching the handle and causing accidents when the machine tool is suspended.

8. When the cantilever crane is in use, all sudden repairs are strictly prohibited.

9. When working, no one is allowed to stand under the boom.

10. Do not drag heavy objects.

11. When not in use, the cantilever crane should be placed at the place, and it is not allowed to park at will.

Features of Stainless Steel Cantilever Crane

The lifting capacity can reach 16t.

The stainless steel cantilever beam is made of standard sections into a box structure. The column is made of standard stainless steel pipes.

The structure has good rigidity, high strength, simplicity and beauty.

Push button operation saves labor input and improves the working efficiency of the whole working condition.

The column can be fixed with embedded anchor bolts, which is easy to install.