10 Tips To Get Custom Stainless Steel Crane

When considering a custom stainless steel crane, it's essential to focus on specific requirements and configurations to ensure it meets your operational needs. Here are ten tips to guide you through the process:

Load Capacity: Specify the maximum weight that the stainless steel crane will need to lift and move. This is a crucial factor in determining the crane's design and components.

Span Length: - Indicate the distance or span the crane needs to cover horizontally. This helps in determining the size of the crane runway and the appropriate length of the stainless steel crane system.

Lifting Height: - Specify the vertical lifting height required for the stainless steel crane. This parameter is essential for designing the crane's lifting mechanism and ensuring it meets the height requirements of your facility.

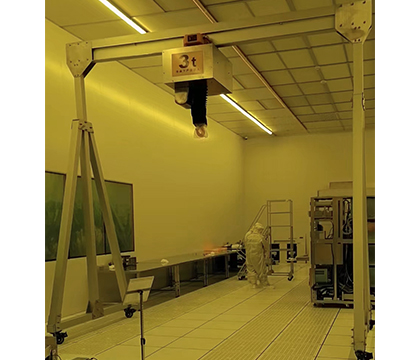

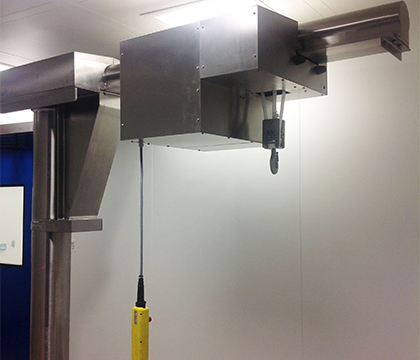

Runway Length and Configuration: - Determine the length and layout of the crane runway. This includes information about whether the crane will be ceiling-mounted, free-standing, or monorail, as well as any curves or switches in the runway system.

Control System: - Specify the type of control system you prefer for the stainless steel crane. Common options include pendant control, radio remote control, or advanced automation systems. The control system choice depends on your operational preferences and safety requirements.

Environmental Conditions: - Provide details about the operating environment, including temperature ranges, humidity levels, and any exposure to corrosive substances. This information helps in selecting appropriate materials and coatings for the crane components.

Duty Cycle and Frequency of Use: - Indicate how frequently the stainless steel crane will be in operation and the duty cycle it needs to support. This information assists in determining the appropriate crane design and components to ensure durability and reliability.

Installation Site Details: - Share information about the installation site, including available space, structural considerations, and any restrictions that may affect the installation and operation of the stainless steel crane.

Regulatory Compliance: - Ensure that the stainless steel crane design complies with relevant safety and regulatory standards in your region or industry. This may include requirements from occupational safety authorities or specific industry standards.

Budget Constraints: - The most important factors that should be considered is your budget. Different brand stainless steel has a large span in prices. And anti corrosion properties will vary in 304 and 316 stainless steels. If you have a budget limitation, communicate it to KFCS SS crane supplier. We can help meet your requirements within the specified budget.

In addition, there are some specific features and requirement can be provided as needed, including the end effectors, anti-corrosion systems, automation capabilities. Just feel free to provide us your requirement.

Contact KFCS to get our stainless steel and other food grade hoists and cranes online and request a free quote or contact us for a custom solution. We've provided the best value in overhead lift systems and hoists, comprehensive services and expert engineering since 2008 with extensive experience providing equipment for food grade environments.