Prepackaged dishes are products that are either finished or semi-finished and are made from agricultural, livestock, poultry, aquatic products, and various auxiliary materials. They are subject to pre-processing methods such as cutting, stirring, pickling, rolling, shaping, and seasoning.

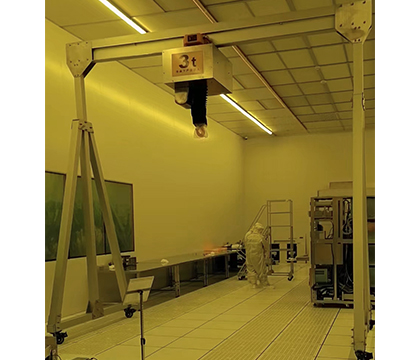

The hygiene specifications for the production of ready meal have strict standards for food safety. For the corrosion problem, we have developed stainless steel cleanroom crane, which can also play a certain anti-collision measure.

Prepackaged food production often involves handling large quantities of ingredients and finished products. A stainless steel jib crane can be installed in various configurations to suit the layout of the cleanroom. They can be wall-mounted or freestanding, with different arm lengths and load capacities available. This flexibility allows them to adapt to different production needs and workflows, maximizing the use of space and resources.

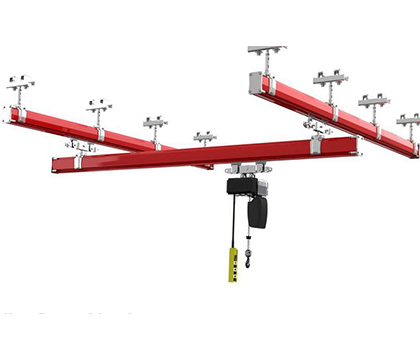

Advantages of Jib Cranes

• Customizable configurations fit in different devices or platforms.

• 360-degree rotation optimize load positioning and access.

• Mechanization reduces manual handling risks and enhances precision during lifting operations.

• Ergonomic designs reduced manual handling

• Equipped with safety features like overload protection, emergency stop buttons, and limit switches.

Stainless Steel Jib Crane Details

Lifting capacity: 2,200 lbs max

Arm profile: Stainless steel

Max arm length: 4000 mm

Working radius: 360°

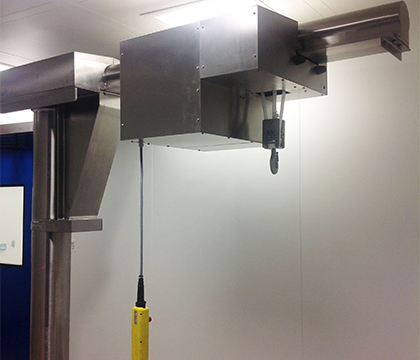

Stainless steel chain hoists are available in either manual or electrically-powered versions, with capacities up to 2 tons. All feature sealed gearing, food grade lubrication, stainless hooks, lifting chain, frames and trolleys.

We are committed to becoming a trustworthy enterprise in the field of clean room lifting system, focusing on technological innovation and improving cranes service capabilities, and creating a safe, lasting, beautiful and friendly production environment for the food industry.