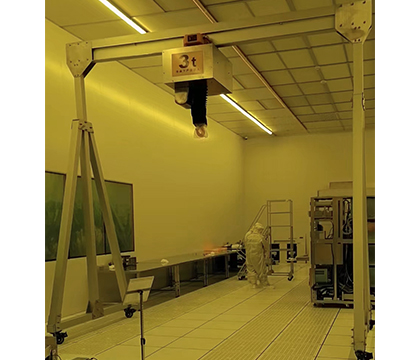

Dust Free Stainless Steel Cantilever Crane

Clean room stainless steel single-arm crane, clean room cantilever crane is used in clean room environment. The working strength of clean room jib crane is light. The crane consists of a column, a slewing arm slewing drive and an electric hoist.

+86-15201969650

info@kfcscrane.com

No.5358 Huyi Road, Jiading District,Shanghai China.

A Dust-Free Stainless Steel Cantilever Crane is a specialized crane designed for clean environments where hygiene and contamination control are critical. It is typically used in industries like pharmaceuticals, food processing, electronics, and cleanrooms.

Clean room stainless steel single-arm crane, clean room cantilever crane is used in clean room environment. The working strength of clean room jib crane is light. The crane consists of a column, a slewing arm slewing drive and an electric hoist. The lower end of the column passes through The anchor bolts are fixed on the concrete foundation, and the cantilever rotation is driven by the cycloidal pinwheel) reduction device. The jib of the crane is a hollow steel structure, which is light in weight, large in span, large in lifting capacity, economical and durable. The built-in running mechanism adopts special engineering plastic running wheels with rolling bearings, which has low friction force and travels briskly; the structure size is small, which is especially beneficial to improve the hook stroke.

Hygienic Surfaces: Smooth surfaces and a polished finish reduce the risk of contamination and make it easier to clean and maintain, which is crucial for industries with strict sanitary requirements.

Corrosion Resistance: Stainless steel's resistance to moisture and chemicals makes the crane durable and long-lasting, even in environments that use cleaning agents, disinfectants, or chemicals.

Cantilever Design: The crane has an arm that extends out from a single point, allowing it to reach over obstacles and access hard-to-reach areas. This design is highly versatile and ideal for handling materials in restricted spaces or over machinery.

Customizable: Stainless steel cantilever cranes can be customized in terms of load capacity, arm length, and lifting mechanisms (manual or electric), depending on the specific needs of the environment.

Stainless steel cantilever crane operates with minimal noise and friction, which is important for maintaining a controlled and clean environment, particularly in noise-sensitive or sterile operations. Contact KFCS to learn more today!