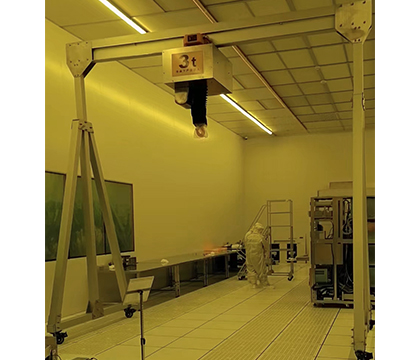

Clean Room Crane for Electronic Chip Industry

In the field of semiconductor chip manufacturing, clean room cranes provide dust-free, precise, and efficient material handling solutions for the production process.

• Maintain Clean Room Environment

Chip manufacturing requires extremely strict environmental cleanliness standards to ensure high-quality and efficient performance. Even the smallest dust particles can impact chip performance and yield. To minimize dust generation during operation, cleanroom cranes utilize special materials and designs, such as stainless steel construction and anti-static coatings. The handling process is carried out within a closed system, and high-efficiency filtration devices maintain strict environmental control, ensuring ultra-clean production conditions and the production of high-quality chips.

• Optimize Handling Efficiency

The efficient operation capabilities of clean room cranes significantly reduce material handling time and improve the operating efficiency of the production line. Through automated handling, manual operation errors and time are reduced, the production process is optimized, production costs are reduced, and overall production efficiency is improved, ensuring the continuity and stability of chip manufacturing.

• Safe Maintenance for Chip Devices

During the maintenance and upgrade of equipment, clean room cranes can safely lift and move large equipment, such as photolithography machines, etching machines, etc., ensuring that no contaminants are introduced during the maintenance process. Its built-in safety mechanism and intelligent control system ensure operational safety, reduce downtime, and improve equipment availability and production stability.

• Customized Lifting Solutions

For the special needs of chip manufacturing, clean room cranes can be customized, including customized fixtures, special lifting devices and customized control systems to adapt to equipment of different sizes, shapes and weights, ensuring that the best quality can be provided in various working scenarios. The best moving solution.

In summary, the application of clean room cranes in semiconductor chip manufacturing has improved the technical level and production efficiency of the industry through its maintenance of ultra-clean environments, optimization of production processes, safe operations and customized services. They are indispensable tools in the field of chip manufacturing and provide solid technical support for promoting innovation and progress in the semiconductor industry.